Testing¶

Written by Grace Lo & Rachel Yan

This test log follows reverse chronological order, with the most recent updates at the top.

Post-Pond Tests¶

The pond test feedback included two requests:

- Change the cycle structure to immediately begin measuring once the chamber is closed

- Find a smaller portable battery option

Oct 27, 2025 Update¶

After analyzing data from the pond test, some methane data seemed to be lost in the ~10 min wait time after closing the chamber. As such, the chamber sequence was changed to a 25-minute cycle as follows:

- Open chamber (~20 s)

- Wait (9 min 20 s)

- Close chamber (~20 s)

- Sensor reads every 5 sec (15 min)

- Repeat

A long term test of the electronic system was completed to determine a battery life of 77:29:52 with more frequent motor use. Accordingly, the power draw increased from ~1 W to ~1.15 W.

Dec 12, 2025 Update¶

The original battery was a Voltaic Systems V88 portable battery with 88.8 Wh capacity, 5 and 12 V output ports, and an always-on feature. It was initially chosen for its variable output voltage that can directly connect to the 12 V motor and its always-on feature. It lasts on average 80 hours, however the product has since been discontinued and we had to search for a new option, ideally with a target run time of 6-12 hours.

Due to the Raspberry Pi Pico's low current draw, regular portable chargers cannot detect a device connection and will turn off after a short period. However, as we were testing new battery options, we discovered the flux chamber system draws enough current to bypass this smart turn off feature (we hypothesize that this is because of the motor current draw). This is very exciting! Because as long as we can step up the output 5 V to 12 V for the motor, any commercial portable battery can power our system. Adafruit's booster cable makes this simple by stepping up 5 V outputs to 12 V, with the USB-A end connecting to the portable battery and the 2.1 mm barrel plug end connecting to the motor driver.

This new power system was tested using a Voltaic Systems V25 portable battery with 6,700 mAh / 24.12 Wh capacity and 5 V output port. It ran for over 20 hours with charge remaining, far exceeding the 6-12 hour requirement. So I would recommend choosing a portable battery with $Battery$ $Capacity$ $(Wh) = 1.5$ $(W) × x$ $(hours)$ where $x$ is the desired run time and the power draw has been rounded up for contingency.

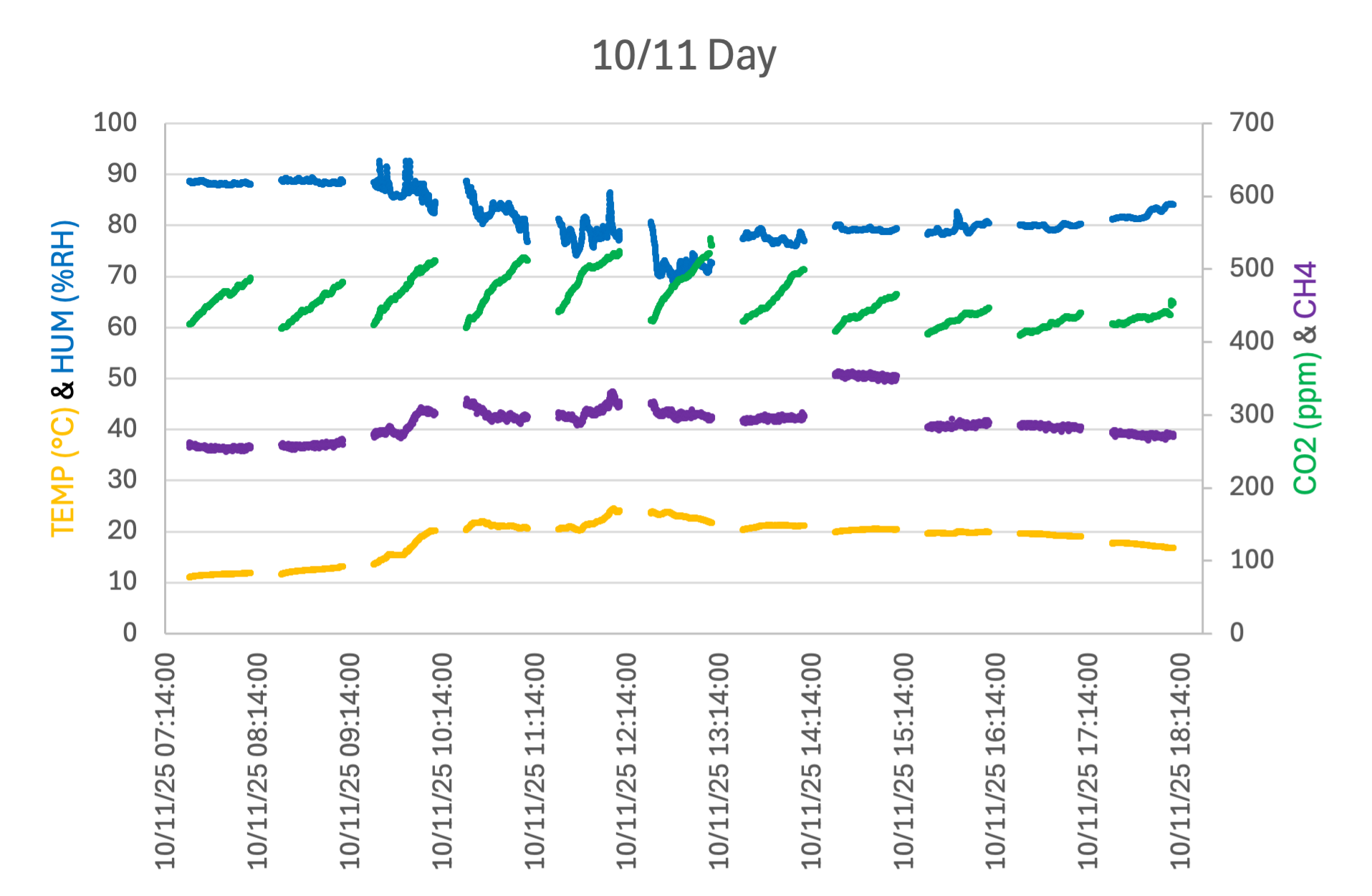

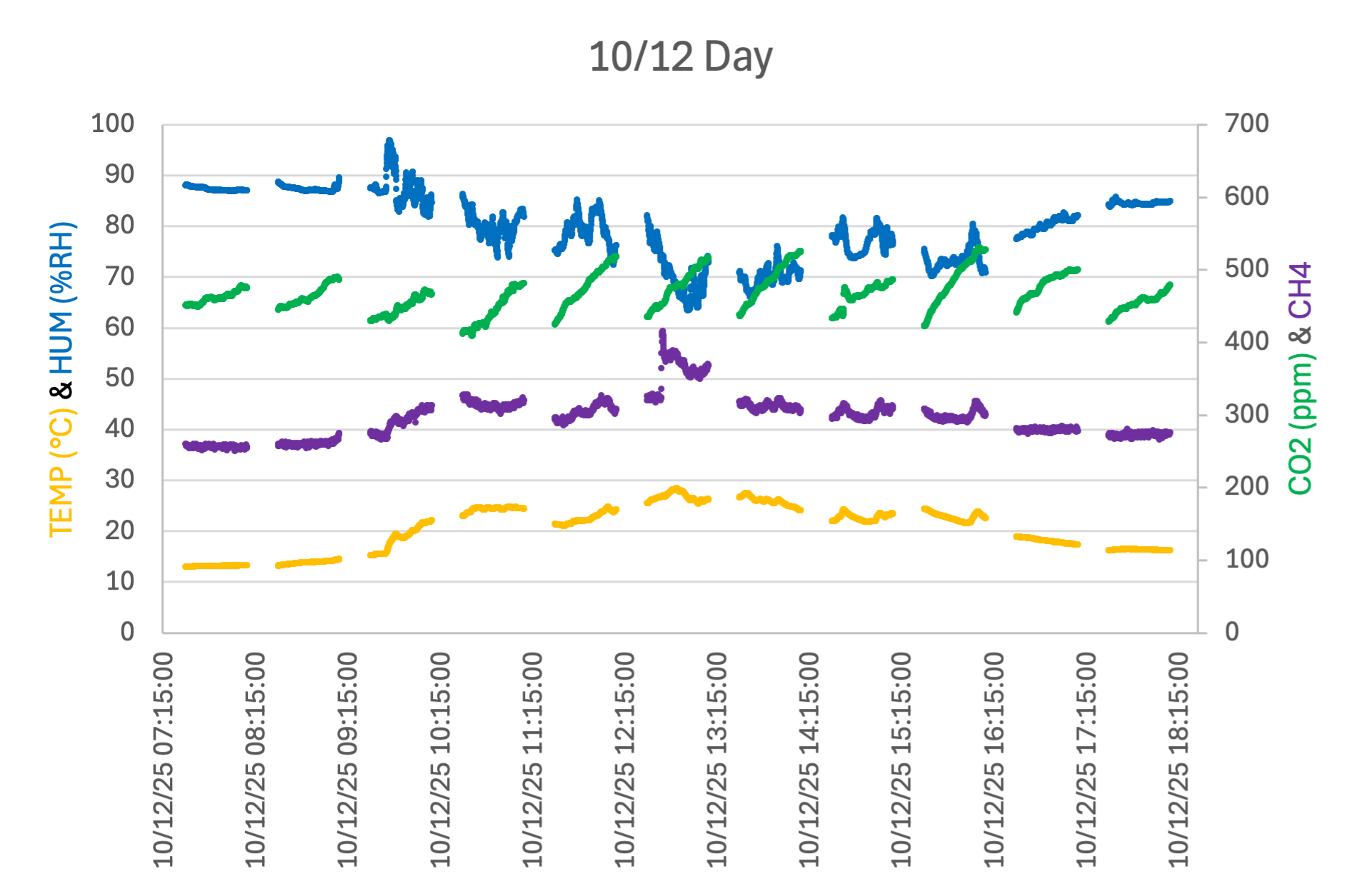

Pond Test¶

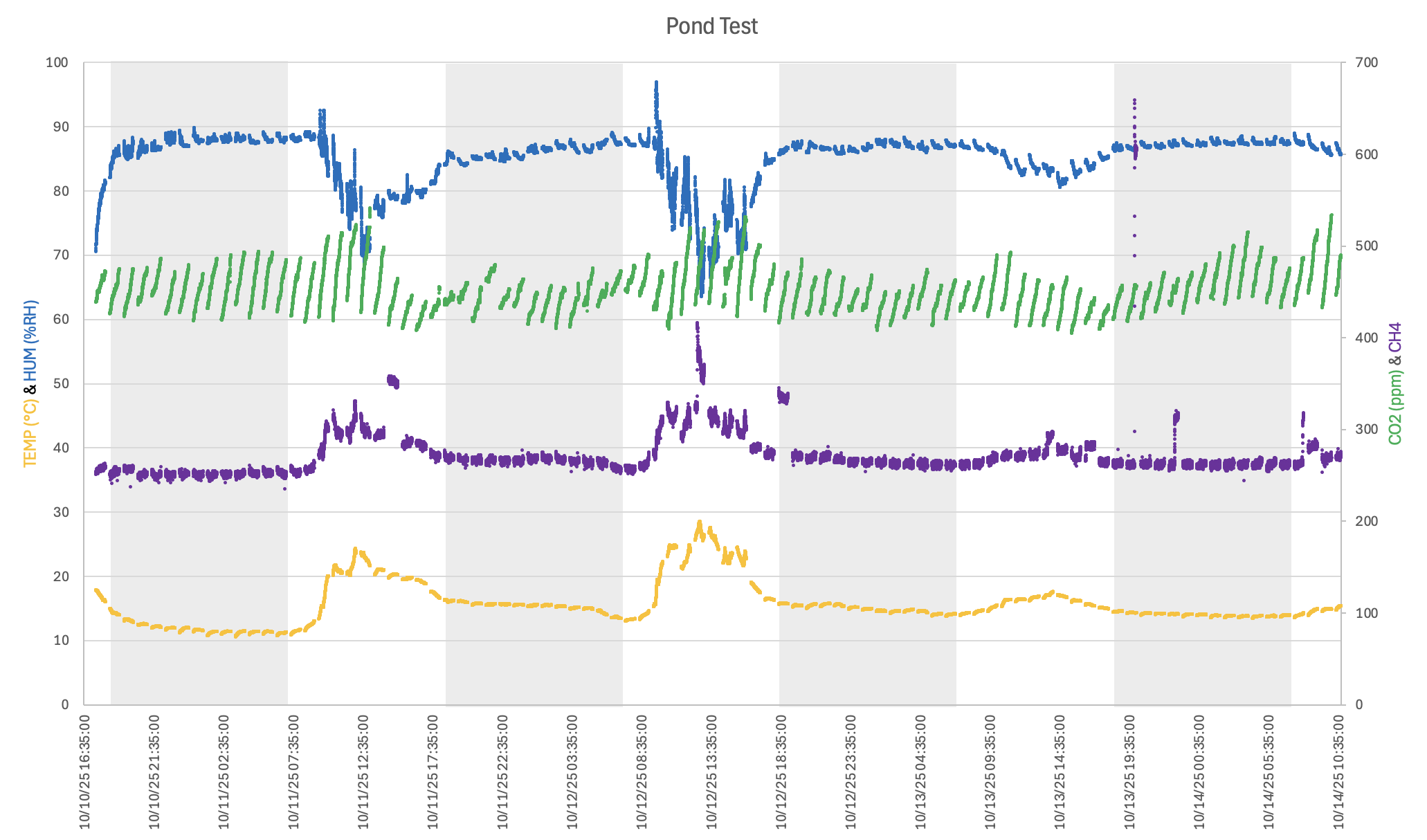

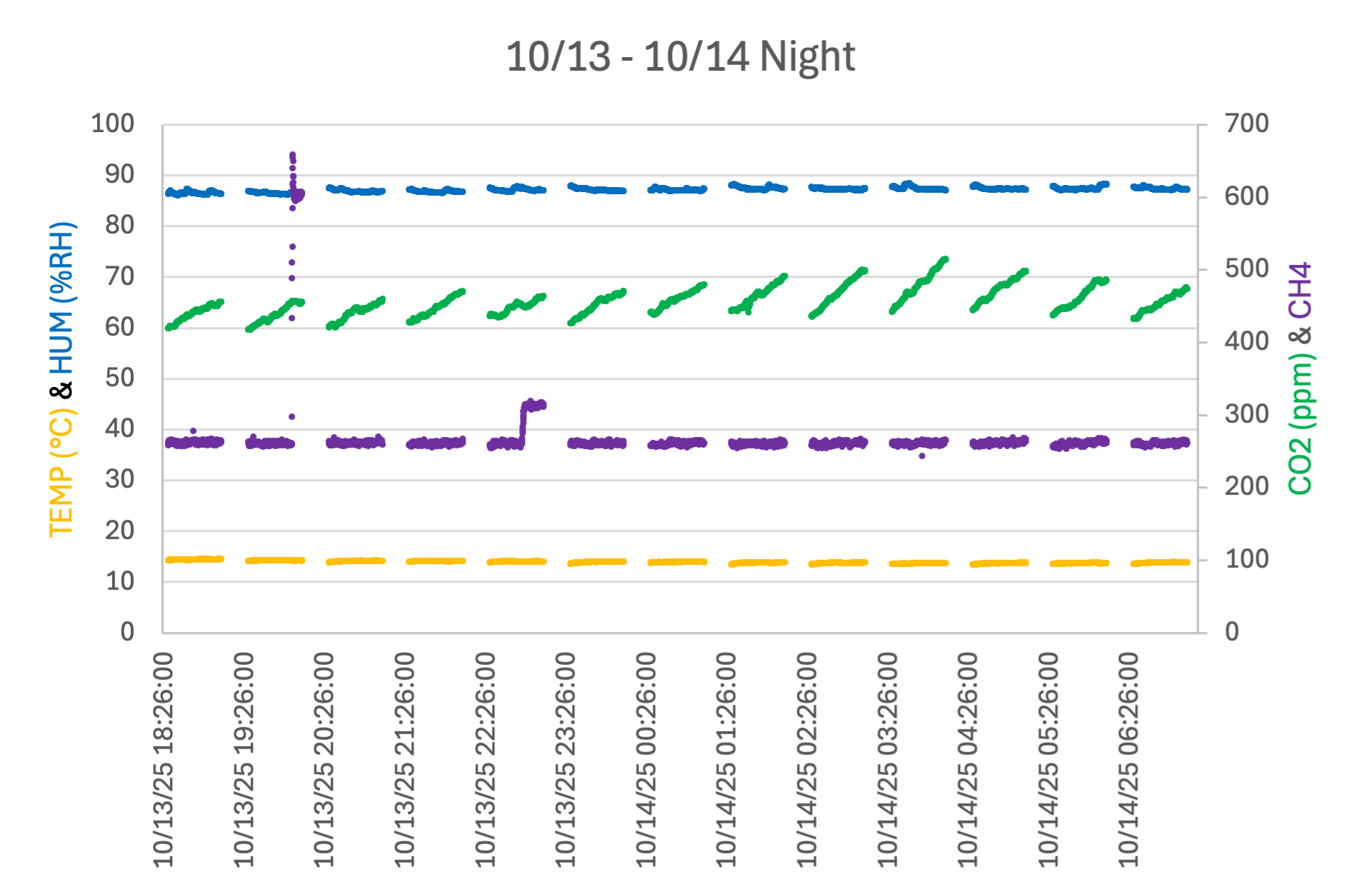

Oct 14, 2025 Update¶

We took the chamber out to a 12 ft deep pond for a weekend test, where it underwent 0.6 inches of rainfall. It was equipped with 1 ft leg supports for extra stability in windy conditions, a waterproof, UV-protected tarp to shield the battery, and a brick to anchor the structure. Deployment went smoothly - the battery was turned on and legs were attached on land, then the system was paddled out to the middle of the pond.

The chamber was set to run on an hour-long cycle following a sequence of:

- Open chamber (~20 s)

- Wait (9 min 40 s)

- Close chamber (~20 s)

- Wait (9 min 40 s)

- Sensor reads every 5 sec (40 min)

- Repeat

The 1st 10 minutes (step 1 & 2) opens and flushes the chamber through passive air flow. The 2nd 10 minutes (step 3 & 4) seals the chamber and waits for external conditions to settle before starting the measurements. The remaining 40 minutes is dedicated to sampling at 0.2 Hz. Note that the sensor logging is paused during the first 20 minutes of each cycle, resulting in data gaps. The chamber was retrieved once the 88.8 Wh portable battery ran out of charge. For clarity, the night hours defined by sunset to sunrise are shaded in gray. Here is a summary of results:

- 90:35:01 elapsed time

- 43,088 data points

- 10 invalid data points

- 90.584 cycles

- 476 avg data pts per cycle

Float Tests¶

Sep 16, 2025 Update¶

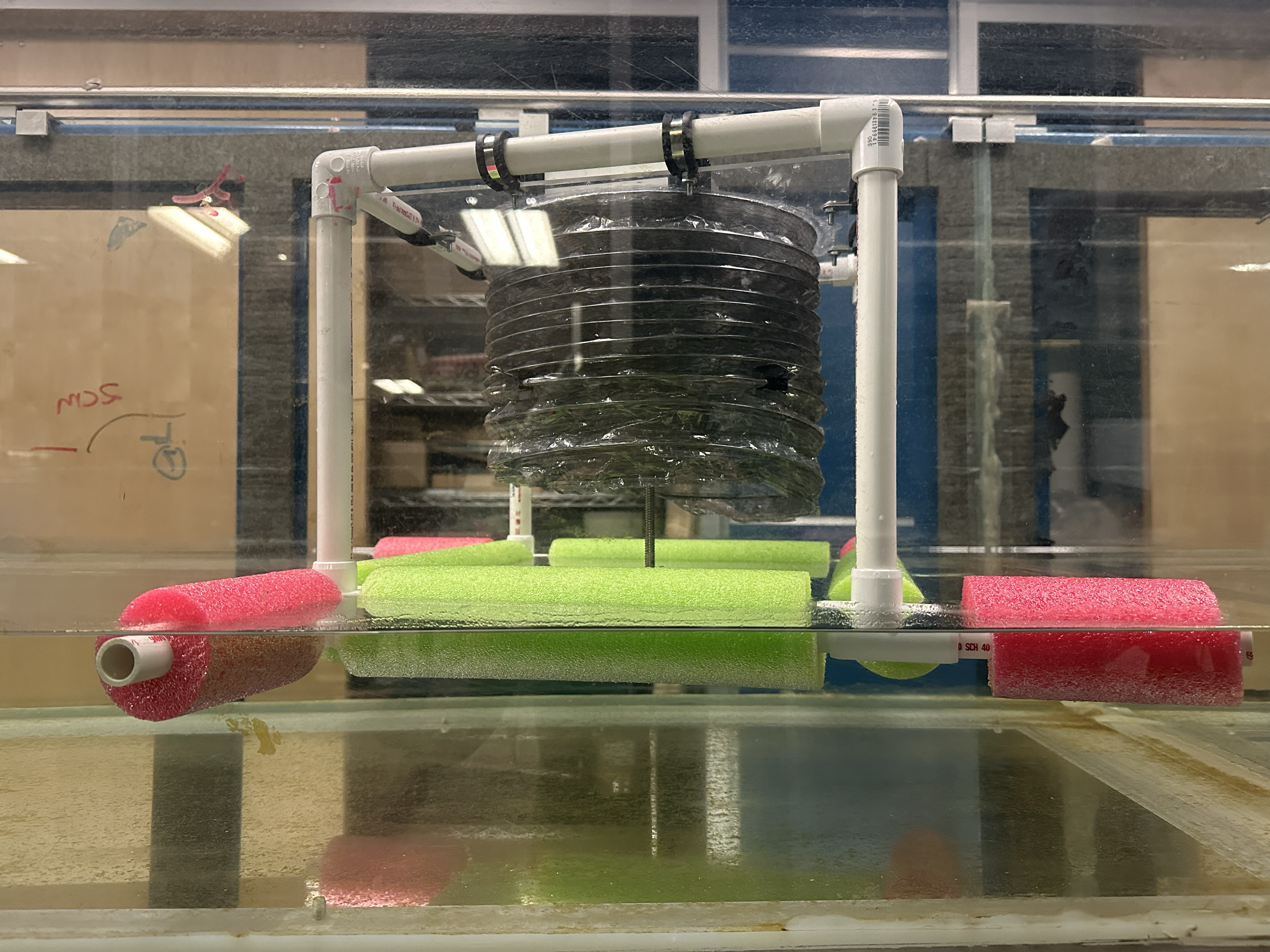

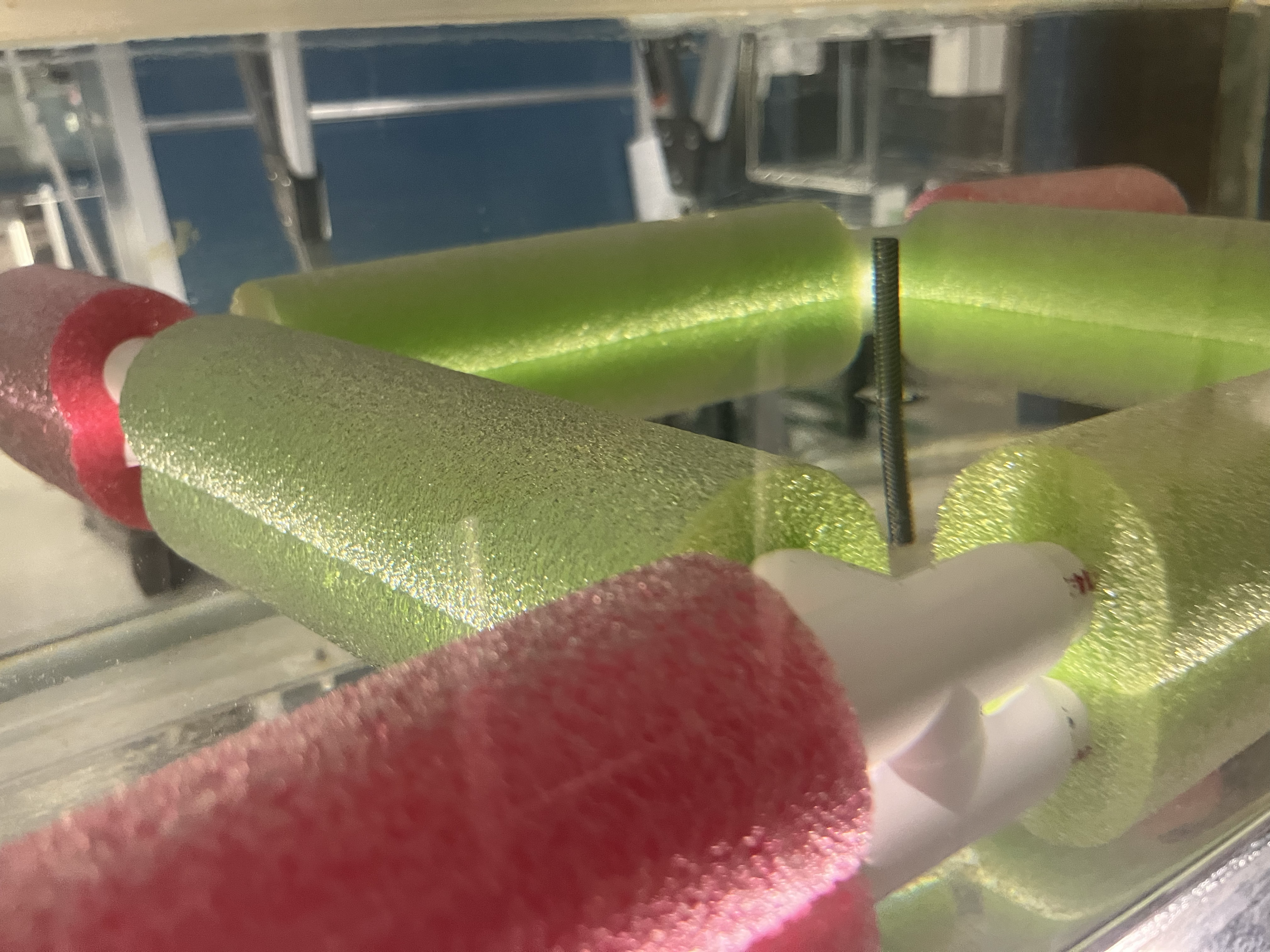

We took the chamber to DeFrees Hydraulics Lab for float testing and it was a success! Pictures and videos are provided below. The chamber without the portable battery can float with the current design structure, however the significant weight of the battery (1.57 lbs) requires additional leg supports. These legs provide stability by distributing the weight across a larger area and buoyancy through additional pool noodles.

- 6 in legs provide just enough buoyancy for the entire structure, with the ability to balance and support the weight even when the battery is not centered.

- 1 ft legs add a bit more stability.

- 2 ft legs are likely overkill.

Chamber Mechanism & Long-Term Tests¶

Aug 15, 2025 Update¶

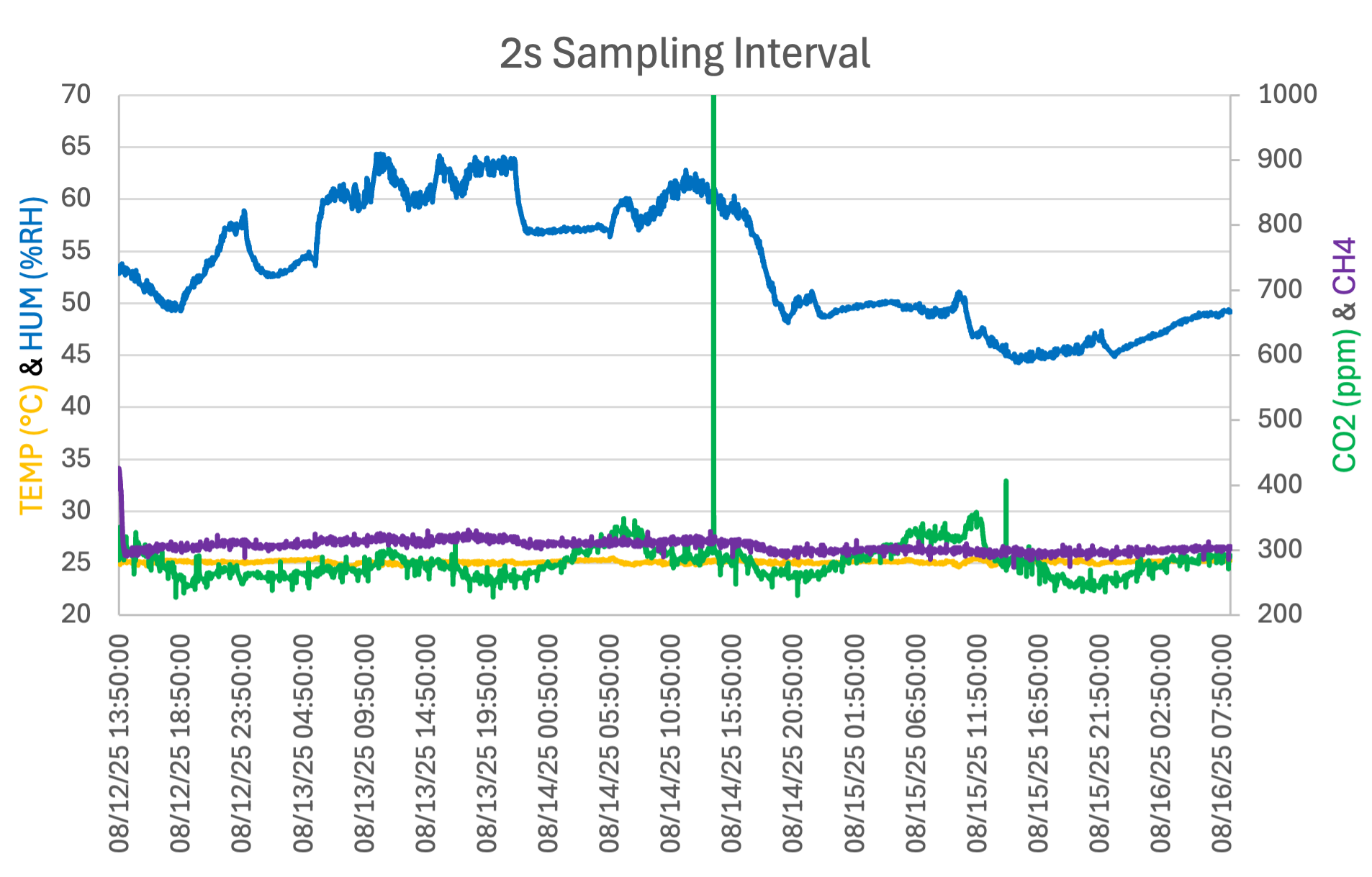

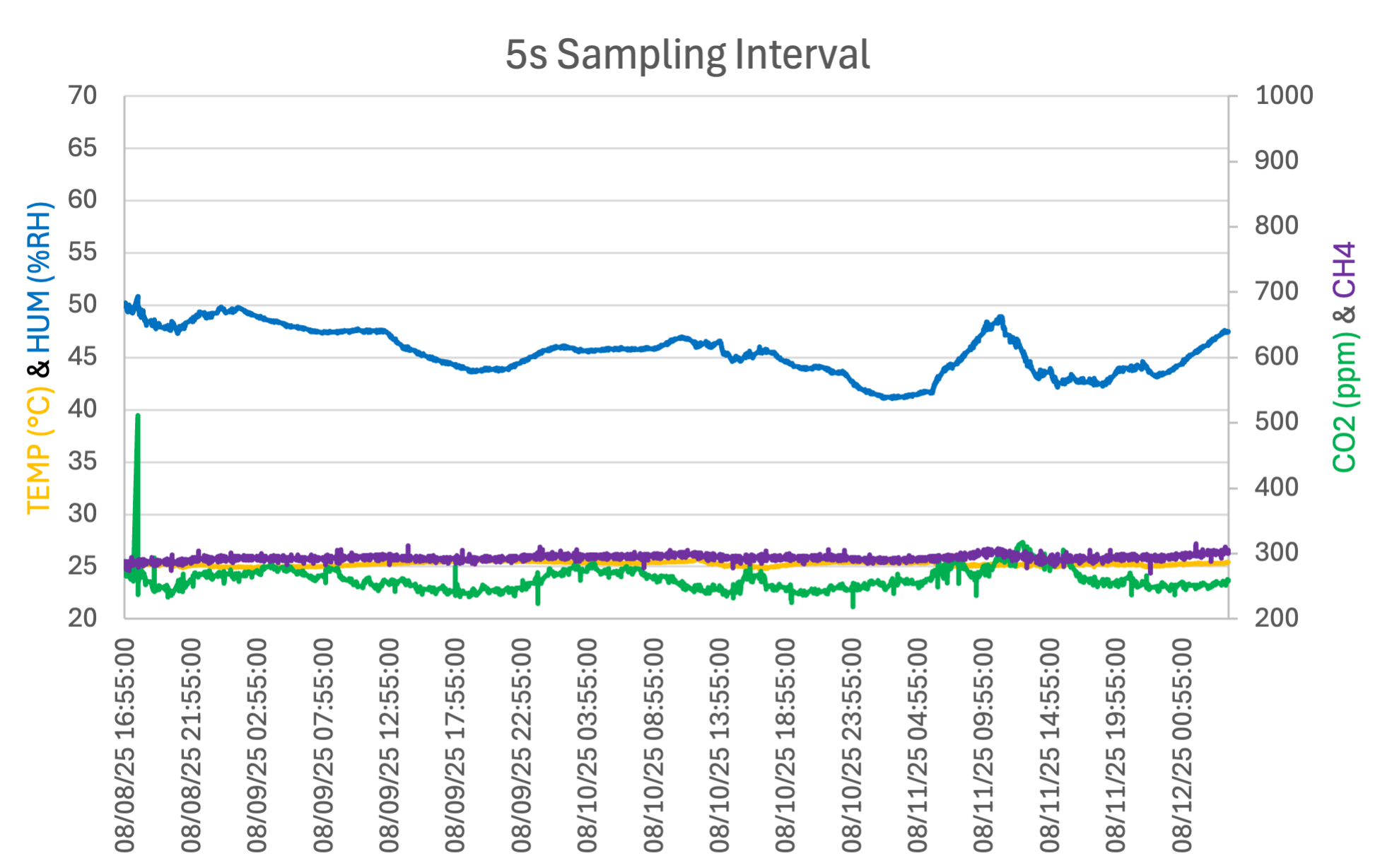

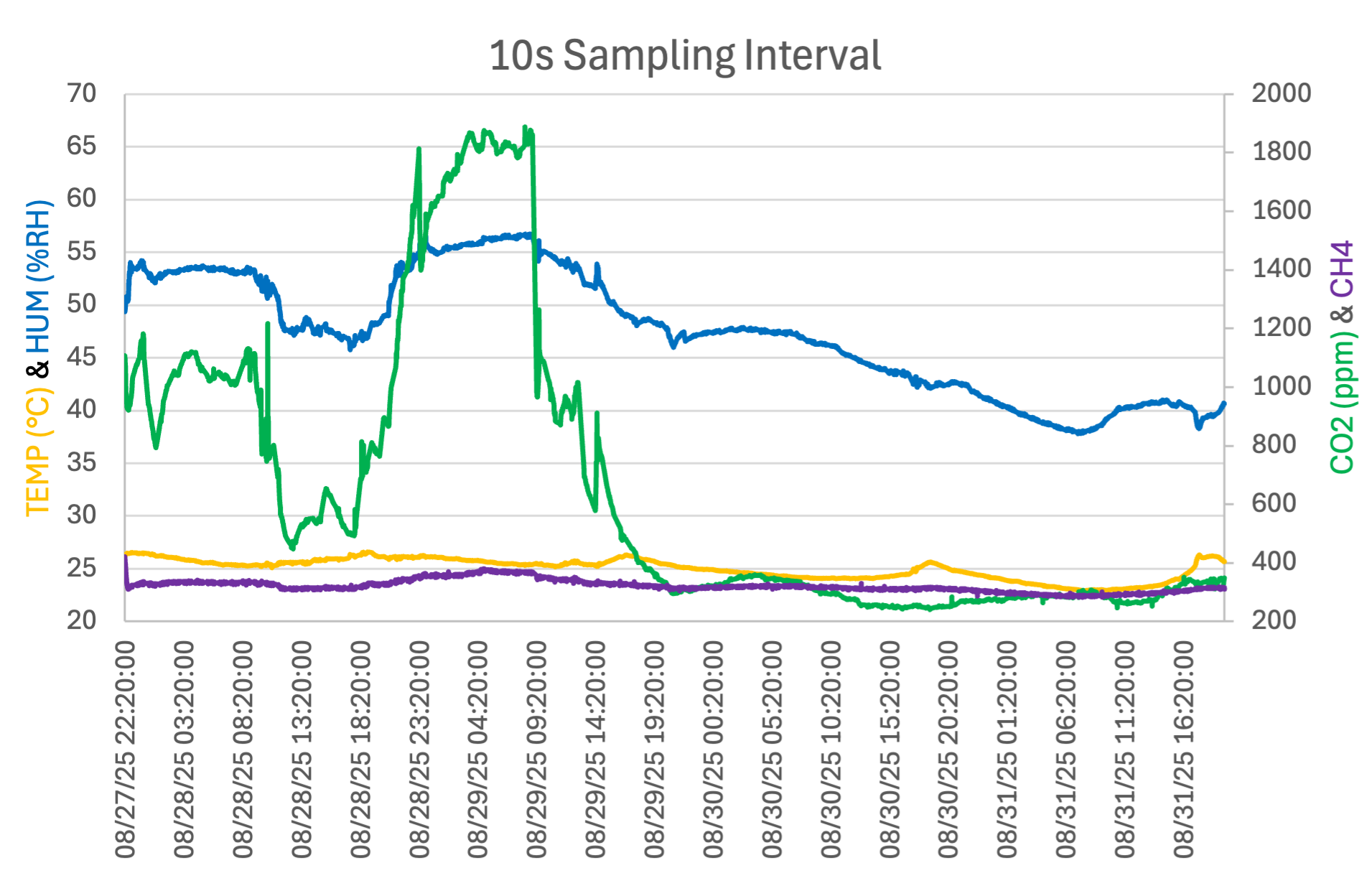

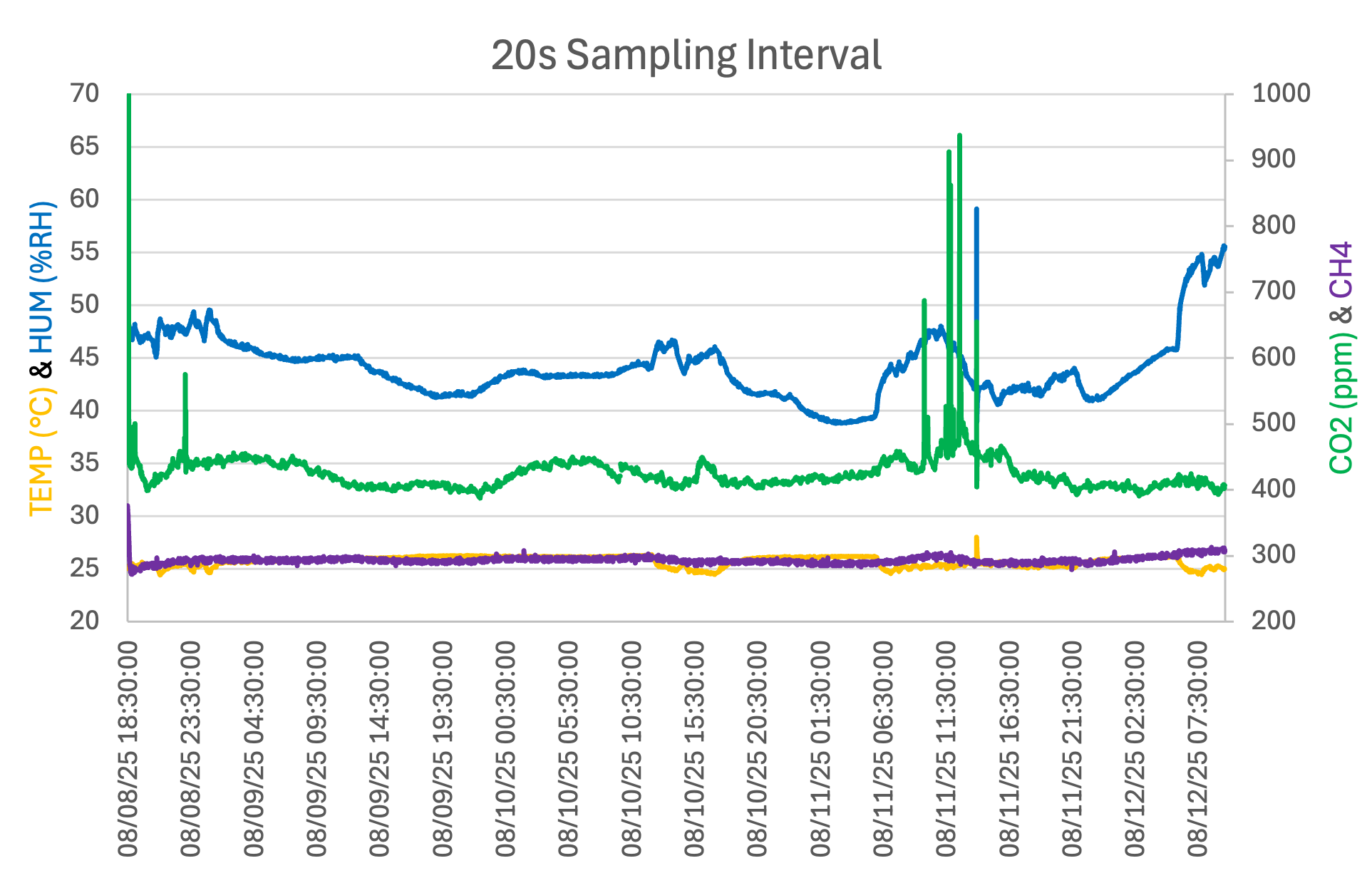

Since the previous update, there have been changes to the motor, methane sensor wiring, feedback switches, and overall error protection of the system. Testing was completed with the time frame of 20 minutes airing out the chamber and 40 mins of data logging at a sampling interval of 2 seconds, which was used in previous prototypes. This means much faster sampling and a significant increase in logged data as compared to previous tests. Many tests have been conducted to debug long deployment issues concerning system freezes and time drift. Optimizations have also been made to reduce power and the number of invalid data points. At present, extended tests spanning 80 hours confirm no system freezes or time drift; the system operates as expected until it runs out of battery. Here is a video demonstration of the chamber system thus far. Without the presence of water, the float switch is triggered by manually moving the float up.

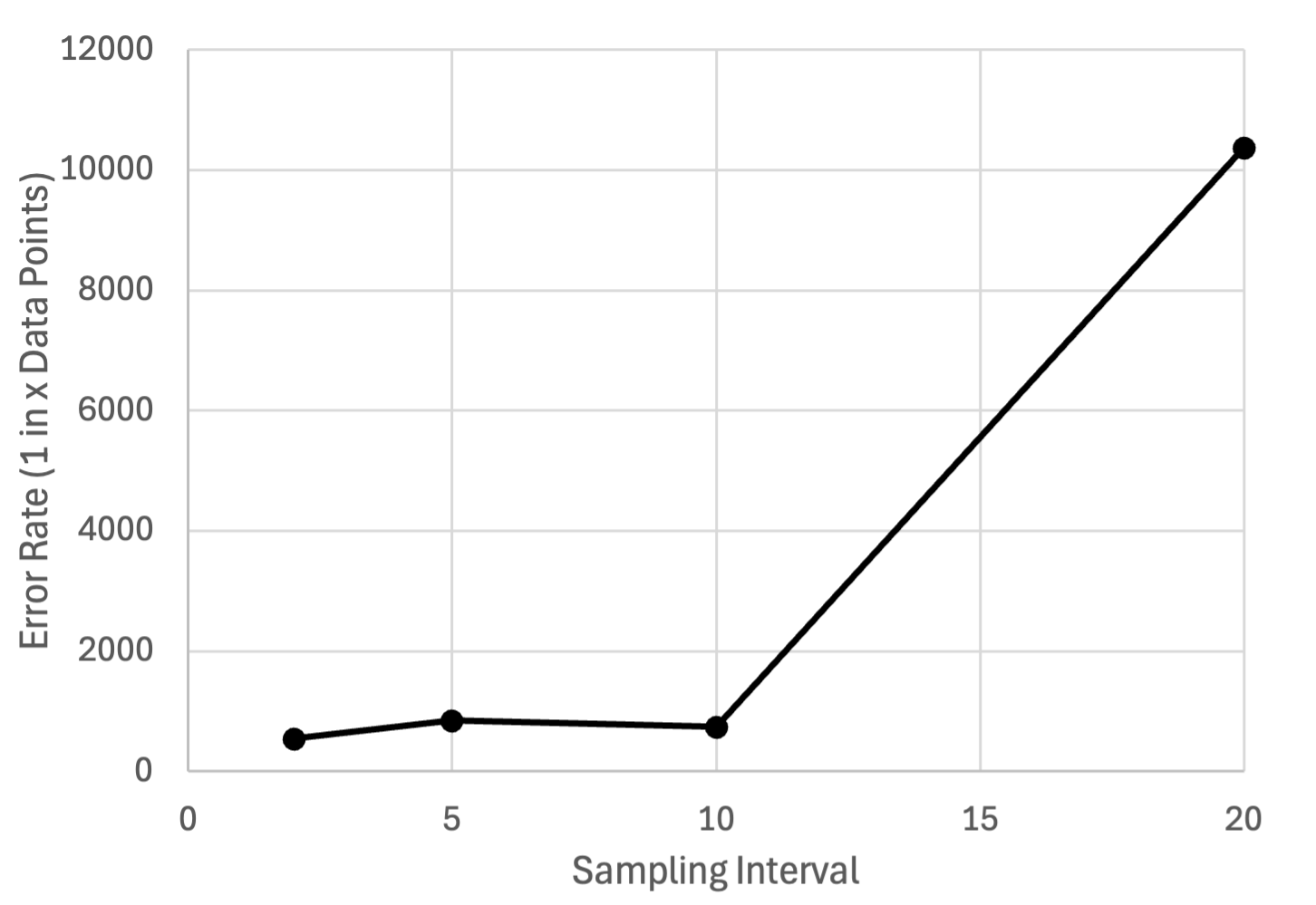

The only error that persists in the system is I²C communication with the Sensirion SCD30 sensor. Although failed transactions cannot be completely eliminated, the rate of error can be improved based on the sampling interval, that is to say, increasing the sampling interval decreases the chance of errors. The most recent testing on the PCB seeks to diagnose the effect of sampling interval on the number of invalid data points. The tests consist of the following sequence:

- Open chamber (21.3 sec)

- Wait (9 min 38.7 sec)

- Close chamber (21.3 sec)

- Wait (9 min 38.7 sec)

- Sensor reads every x sec (40 min total)

- Repeat

The graph below illustrates the findings thus far: sampling intervals between the 2 to 10 second range have comparable error rates, however drastically increasing the sampling interval to 20 seconds greatly improves the error rate. Further testing will be completed on other sampling intervals to continue mapping out such behavior.

The experiments used an 88.8 Wh portable battery charged to full capacity, with battery life varying between 80 and 90 hours. This comes out to a power draw of ~1 W, which when connected to a solar panel, has the potential to run indefinitely.

|

|

|

|

Electronic Tests¶

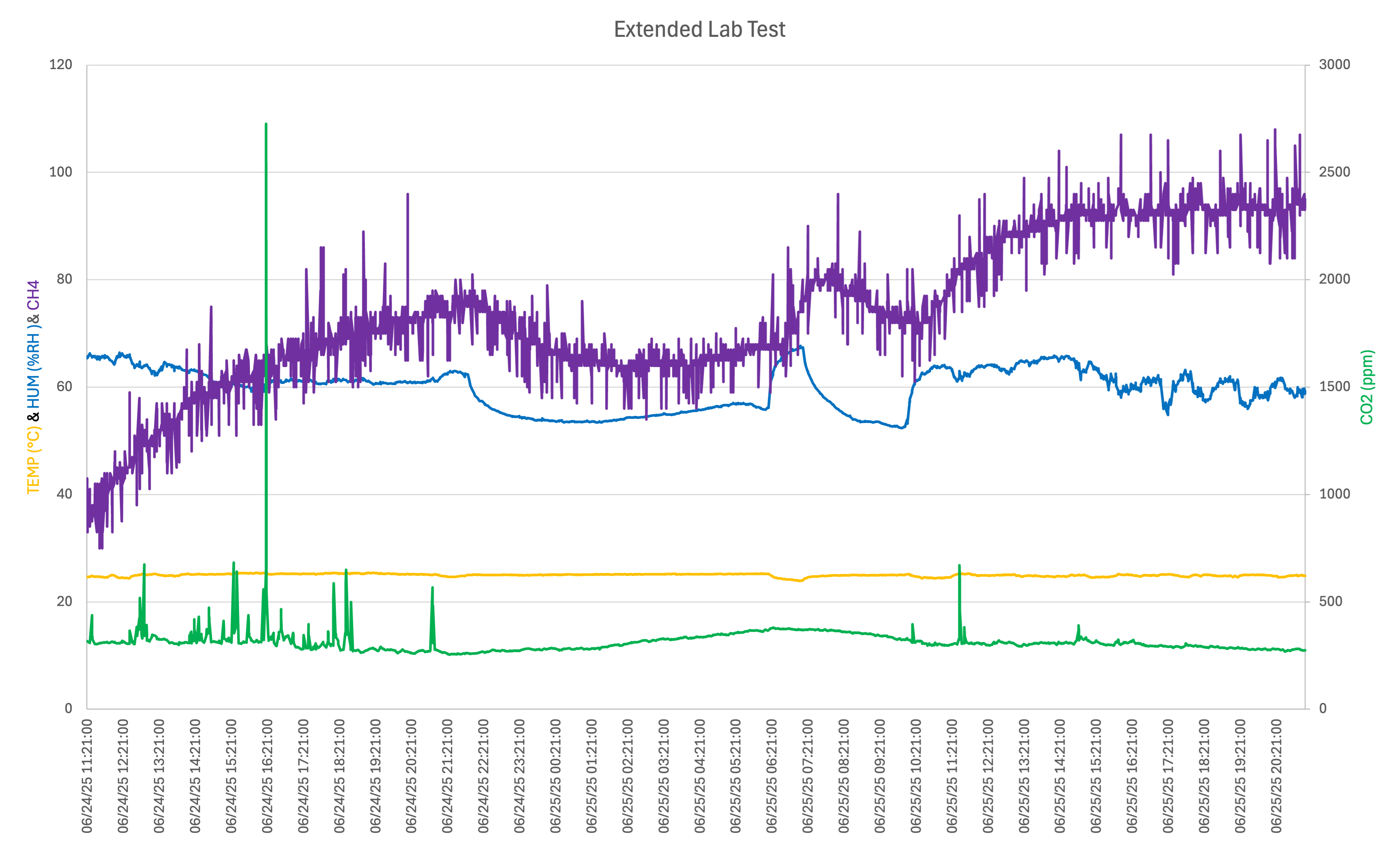

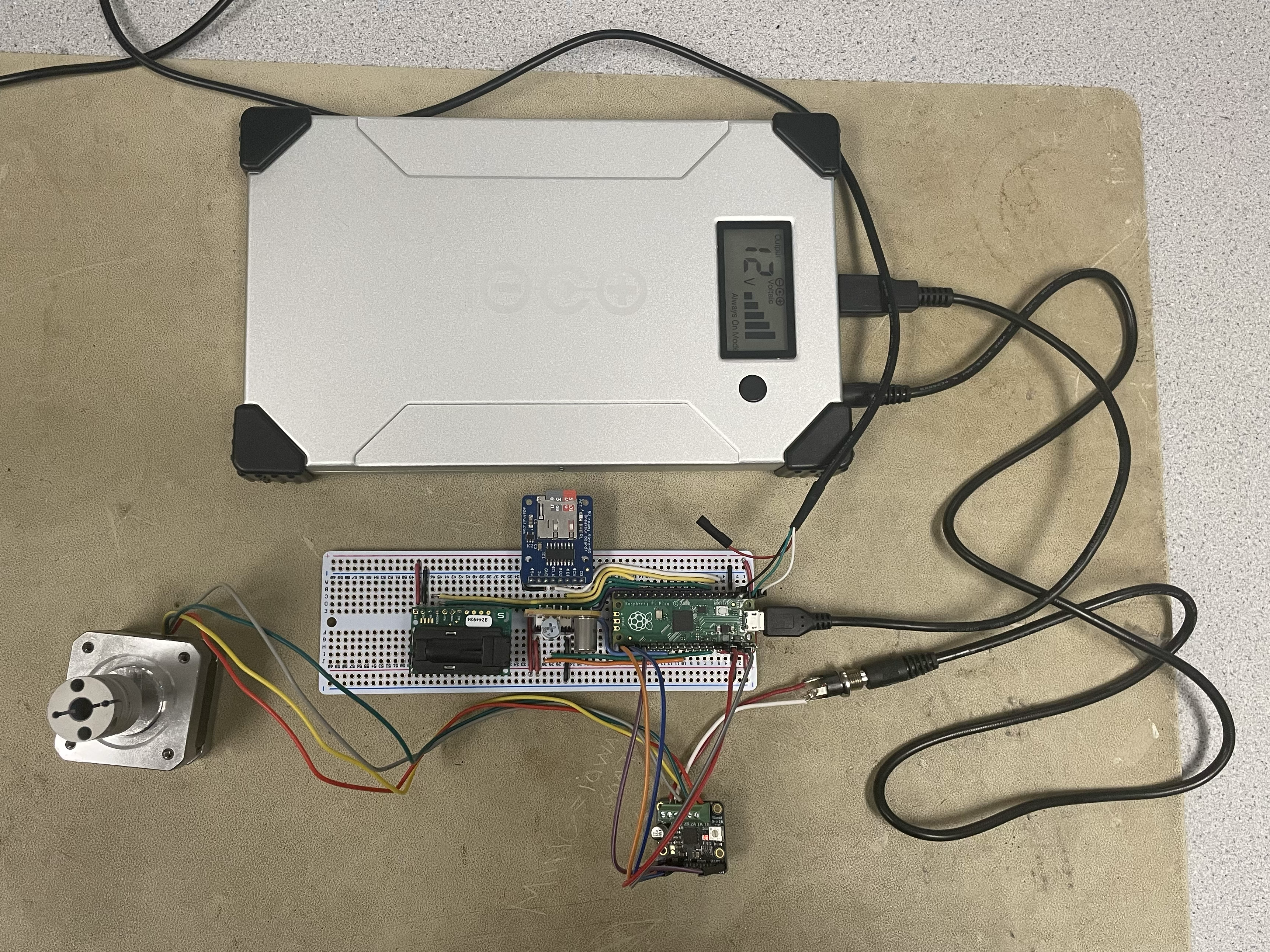

Jun 26, 2025 Update¶

We conducted an extended test of the electrical system untethered. This means that the Raspberry Pi Pico and the motor were connected to a portable battery and left to run until the battery ran out. It is important to note that the portable battery had been used for small-scale testing beforehand so it was not at its full capcity. In addition, the battery was tested on many short cycles, so presumably, longer cycle times can drain more battery than the current power per cycle estimate. The testing cycle followed a sequence of:

- Open chamber (~1 min)

- Wait (0.5 min)

- Close chamber (~1 min)

- Wait (0.5 min)

- Sensor reads every 10 sec (1 min total)

- Repeat

All systems performed as expected. Highlights include:

- 33:48:03 elapsed time

- 2,945 data points

- 1 dropped data point (row 1103, 12 hrs 37 min and 26 sec in)

- 491 cycles

The data was logged in a .csv file that was converted to a .xlsx file for advanced graphing purposes.